|

|

|||

|

|

Research Focus The biosensors laboratory focuses on development of wireless

implantable sensors for human physiological measurements. Current research

interests include the magnetic harmonic sensors, the inductor-capacitor

resonant-circuit (LC) sensors, and the magnetoelastic sensors. This

laboratory also collaborates with Engineered

Biomaterials Laboratory to develop a magnetoelastic vibrational coating for suppressing

biofouling and controlling cell proliferation. This

laboratory is equipped with standard device fabrication instruments

such as circuit fabrication station, as well as device characterization

equipments such as high-frequency spectrum/network analyzers, waveform

generators, and various amplifiers and filters. This lab is also

capable of rapid prototyping with equipments such as a CNC milling

machine, a 3D printer, and a 3D scanner. This lab also has standard

chemistry equipments for sensor functionalization. |

||

|

|

Magneto Harmonic Shift

Sensors The magneto

harmonic shift (MHS) sensors are based on two adjacently placed ferromagnetic strips: one

magnetically soft and the other magnetically hard. When the separation

distance between these two strips varies, the magnetic signature from the

soft magnetic strip changes, allowing wireless detection of the sensor

response by measuring the change in induced magnetic field. |

||

|

|

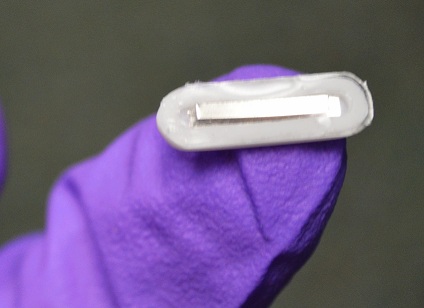

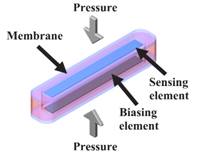

Pressure monitoring in abdominal aortic aneurysm sac The

implantable pressure sensor is designed for monitoring pressure inside

an abdominal aortic aneurysm sac. Changes in ambient pressure deflect

the membranes, thus changing the separation distance between the

biasing element (hard magnetic strip) and sensing element (soft

magnetic strip). This alters the sensor signature allowing remote

pressure monitoring by measuring the changes in magnetic field. |

||

|

|

|||

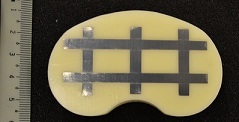

| Magnetoelastic Harmonic Sensors This

wireless force mapping sensor system is designed for real-time

monitoring of compressive forces on knee implants. Since magnetoelastic

material changes its magnetization property with the applied force, an

array of magnetoelastic strips, detected via a set of detection coils,

can be used to map the surface profile on a knee implant (the PE

insert) wirelessly. | ||

|

|

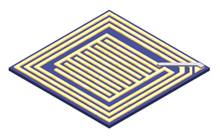

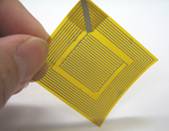

Inductor Capacitor Resonant Circuit Sensors The LC sensor is made of

a planar inductor and capacitor printed on a substrate. To monitor parameters

of interest, the sensor is embedded inside the test medium and its response is

remotely detected through a coil connected to a sensor reader. Parameters

such as humidity and various gases are detected by applying a chemically

responsive coating on the capacitor. As the target parameter changes, the

coating changes the capacitorís capacitance and this leads to changes in the

sensorís resonant frequency. The biosensors laboratory is currently applying

this sensor technology for monitoring food quality and humidity inside civil

infrastructures. A wound healing monitoring sensor is also being fabricated

based on the LC sensor technology. |

||

|

|

|

||

|

Various designs of the

inductor-capacitor resonant circuit sensors |

|||

|

|

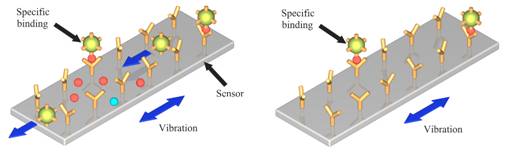

Magnetoelastic Sensors Another

focus of this lab is the development of a disposable sensor for rapid

microbial detection. Potential applications include controlling of food

quality and safety (E. coli) as well as monitoring nosocomial

infections (MRSA). The sensor is based on an array of magnetically

interrogated, vibrating magnetoelastic sensors functionalized with proteins,

antibodies and/or phages. Bacteria detection is realized by tracking the

change in the resonance frequency and/or amplitude of the sensor, which is

caused by the mass increase when the bacteria bind to the functional coating.

The strength of the bonds is also measured by linearly increasing the sensor

vibration until a bond-breaking event is observed. Specific bacteria

identification is achieved by analyzing the bond strengths between the target

bacteria and the sensor array. |

||

|

|

|||

|

(Left) Target analytes

attached to the sensor. (Right) Sensor vibration removes non-binding analytes

from its surface. |

|||

|

|

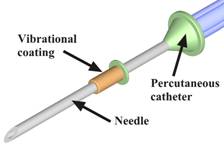

Magnetoelastic Vibrational Coating In collaboration

with the Engineered Biomaterials Lab, we are developing a remotely controlled

antifouling coating for reducing biofilm growth on biomedical implants. The

coating is based on a magnetoelastic layer that vibrates in the presence of a

magnetic AC field. Through an adjacently located device that generates

controllable magnetic fields, the coating can be set to vibrate at a

predetermined amplitude and frequency as a means for biofilm growth

management. The novelty of this technology is that the coating characteristic

can be remotely altered after deployment in vivo through changing

magnetic field strength. In addition, it is also possible to monitor biofilm

growth on the coating in vivo by measuring the changes in the magnetic

field signature from the coating (coating vibration generates a secondary

magnetic flux that can be independently monitored). The ability to measure

biofilm growth and adjust the coating characteristic in vivo allows

the creation of a smart antifouling coating that can precisely control

biofilm formation by activating the vibration only when it is needed. |

||

|

|

|||

|

|

|||